What it is:

Green Solutions in Music Instruments Manufacturing refers to the implementation of innovative and sustainable methods in the production and manufacturing processes of musical instruments. This approach aims to minimize the environmental impact associated with the creation of musical instruments, considering factors such as resource consumption, energy efficiency, waste reduction, and material sourcing.

Real-World Problems:

The traditional manufacturing practices in the music instrument industry often pose significant environmental challenges. Some of the real-world problems associated with conventional methods include:

1. Carbon Footprint:

The production of musical instruments, particularly those made from wood, contributes to deforestation and greenhouse gas emissions. The extraction, processing, and transportation of raw materials, as well as the energy-intensive manufacturing processes, result in a substantial carbon footprint.

2. Toxic Chemicals:

The conventional use of toxic chemicals, such as lacquers, glues, and dyes, in the manufacturing of musical instruments can have harmful effects on human health and the environment. These chemicals often contain volatile organic compounds (VOCs) and heavy metals that can contaminate air, water, and soil during the production and disposal stages.

3. Waste Generation:

The music instrument industry generates significant amounts of waste during the manufacturing process. This includes excess materials, packaging, and product components that contribute to landfill accumulation and resource depletion. Additionally, obsolete or damaged instruments often end up in landfills rather than being recycled or repurposed.

4. Unsustainable Material Sourcing:

Many music instruments, particularly those made from exotic woods, face challenges related to unsustainable material sourcing. Illegal logging and overharvesting of rare wood species can lead to habitat destruction, loss of biodiversity, and negative social impacts on local communities.

5. Energy Consumption:

Traditional manufacturing processes in the music instrument industry often consume high amounts of energy. This includes operations such as milling, shaping, and finishing, along with the usage of machinery and equipment. The reliance on non-renewable energy sources contributes to carbon emissions and exacerbates climate change.

Solutions for Green Solutions in Music Instruments Manufacturing:

In response to the real-world problems associated with traditional music instrument manufacturing, innovative and sustainable methods are being adopted. These solutions aim to minimize environmental impact and promote a more sustainable future for the industry. Some of the key solutions include:

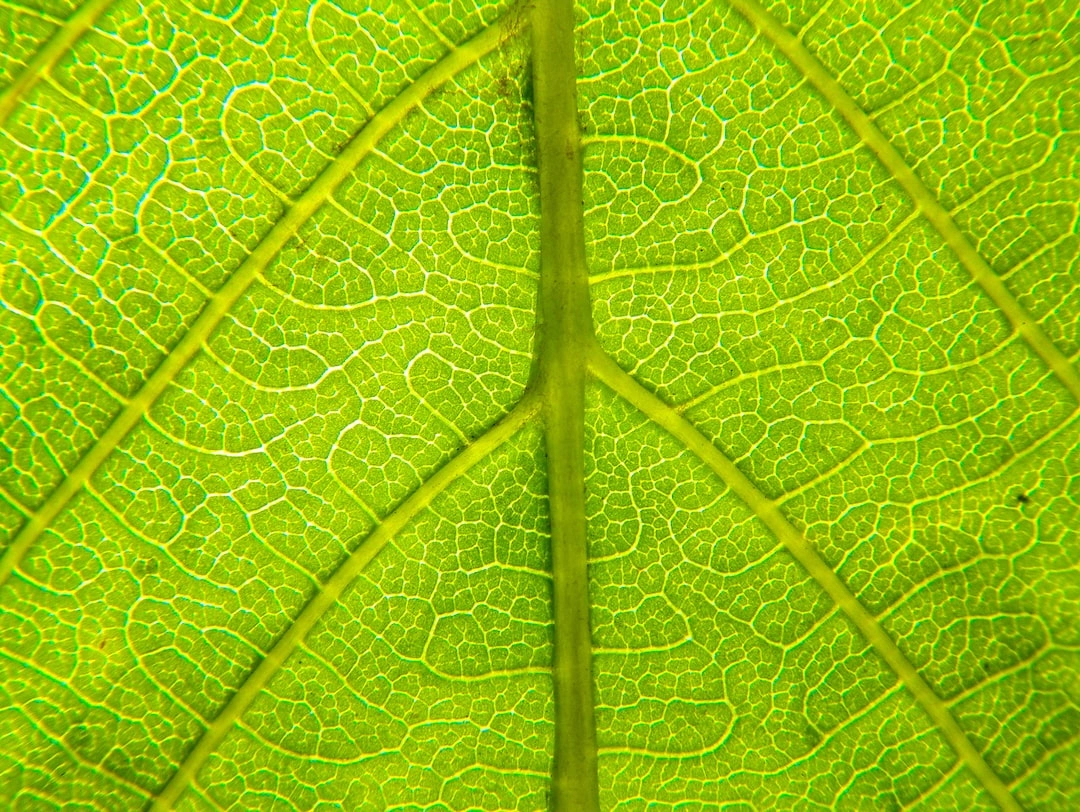

1. Sustainable Material Sourcing:

Music instrument manufacturers are increasingly exploring alternative and sustainable materials. This includes using responsibly sourced woods, such as FSC-certified or reclaimed wood, as well as non-wood alternatives like recycled plastics and composites. By promoting sustainable material sourcing, the industry can reduce habitat destruction, protect biodiversity, and ensure the longevity of resources.

2. Energy Efficiency:

Manufacturers are implementing energy-saving measures throughout the production process. This includes adopting energy-efficient machinery, optimizing manufacturing techniques to reduce energy consumption, and utilizing renewable energy sources such as solar or wind power. By prioritizing energy efficiency, the industry can significantly reduce its carbon footprint and contribute to combating climate change.

3. Waste Reduction and Circular Economy:

Music instrument manufacturers are implementing strategies to minimize waste generation and promote a circular economy approach. This involves optimizing material usage, reducing packaging waste, and implementing recycling and reusing programs for instrument components. By embracing the principles of the circular economy, the industry can minimize waste sent to landfills and conserve valuable resources.

4. Non-Toxic and Environmentally Friendly Materials:

To address the issue of toxic chemicals, manufacturers are seeking alternatives to traditional lacquers, glues, and dyes. They are adopting non-toxic and environmentally friendly materials, such as water-based finishes and adhesives with low VOC content. This helps to reduce air and water pollution while ensuring the safety of workers and end-users.

5. Education and Awareness:

Increasing awareness and educating both manufacturers and consumers about the importance of green solutions in music instrument manufacturing is crucial. Industry associations, musicians, and environmental organizations play a vital role in promoting sustainable practices and encouraging the demand for eco-friendly instruments. By fostering a culture of sustainability, the industry can drive change and inspire others to follow suit.